Zinc Sulfide (ZnS) Windows: Properties, Applications, Manufacturing, and Advancements

Zinc Sulfide (ZnS) windows are essential components in optical systems known for their exceptional performance in the infrared (IR) spectrum. This article explores the fundamental aspects of ZnS windows, including their properties, diverse applications, manufacturing techniques, recent advancements, and future prospects in optical technology.

Introduction to Zinc Sulfide (ZnS) Windows

Zinc Sulfide (ZnS) is a robust material widely used in optical applications due to its excellent optical properties and mechanical durability zns window are transparent optical elements designed to transmit IR radiation efficiently while maintaining high optical clarity and performance in various environmental conditions.

Properties of Zinc Sulfide (ZnS) Windows

ZnS windows exhibit several key properties that make them highly suitable for IR optical applications:

- High IR Transmission: ZnS windows offer exceptional transmission in the infrared spectrum, typically from approximately 0.4 microns (µm) to 12 microns (µm). This broad transparency range allows ZnS windows to transmit IR radiation with minimal absorption, making them ideal for IR imaging, thermal sensing, and laser systems.

- Low Absorption Coefficient: ZnS has a low absorption coefficient in the IR spectrum, ensuring efficient transmission of IR light with minimal loss of intensity. This property is crucial for maintaining optical clarity and fidelity in IR-sensitive applications, including thermal imaging and remote sensing.

- Mechanical and Thermal Stability: ZnS windows are mechanically robust and thermally stable, capable of withstanding temperature variations and mechanical stress. This durability ensures reliable performance in harsh environments such as aerospace, defense, and industrial applications.

- Optical Clarity: ZnS windows exhibit high optical clarity, enabling precise transmission of IR radiation without significant dispersion or distortion. This property is essential for maintaining image quality and spectral accuracy in IR imaging and spectroscopic instruments.

Applications of Zinc Sulfide (ZnS) Windows

ZnS windows are utilized across various industries and applications:

Infrared Imaging and Sensing

ZnS windows serve as optical components in IR cameras and sensors for capturing thermal radiation emitted by objects. They enable clear and accurate IR imaging in applications such as surveillance, industrial monitoring, and medical diagnostics.

Laser Systems

In laser systems, ZnS windows are used as protective windows and optical elements for CO2 lasers operating at wavelengths around 10.6 microns. Their high IR transmission efficiency supports applications in laser cutting, welding, and medical laser treatments.

Aerospace and Defense

ZnS windows are employed in aerospace and defense for IR windows, missile domes, and optical lenses. Their robustness and optical performance enhance situational awareness, targeting accuracy, and reconnaissance capabilities in military and aerospace applications.

Scientific Research

ZnS windows facilitate IR spectroscopy and analysis in scientific research, enabling researchers to study molecular structures, chemical compositions, and material properties with high sensitivity and accuracy.

Manufacturing of Zinc Sulfide (ZnS) Windows

The manufacturing process of ZnS windows involves specialized techniques to achieve high optical quality and performance:

- Material Preparation: ZnS is synthesized through chemical vapor deposition (CVD) or hot pressing methods to produce optical-grade material with uniform properties and high purity.

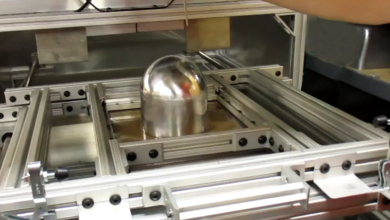

- Precision Machining: Optical components are machined from ZnS blanks using diamond turning or grinding techniques to achieve precise dimensions, curvature, and surface quality according to stringent optical specifications.

- Coating and Surface Treatment: Anti-reflection coatings tailored for IR wavelengths are applied to ZnS windows to enhance transmission, reduce surface reflections, and improve durability. These coatings optimize optical performance in diverse IR-sensitive applications.

Technological Advancements in Zinc Sulfide (ZnS) Windows

Recent advancements in ZnS windows focus on enhancing their optical performance, durability, and integration capabilities:

Advanced Optical Coatings

Innovations in coating technologies improve the spectral performance, durability, and anti-reflective properties of ZnS windows. Advanced coatings enable ZnS windows to withstand higher laser powers, reduce surface scatter, and maintain optical integrity in demanding applications.

Multispectral Imaging Capabilities

Research efforts aim to expand ZnS windows’ spectral capabilities to encompass broader ranges, including UV, visible, and extended IR wavelengths. This expansion enhances their utility in multispectral imaging systems and advanced optical technologies.

Integration with Emerging Technologies

ZnS windows are increasingly integrated with emerging technologies such as quantum optics, photonics, and optoelectronics. These integrations enable compact, high-performance optical systems for telecommunications, sensing, and advanced imaging applications.

Future Directions for Zinc Sulfide (ZnS) Windows

The future of ZnS windows is driven by ongoing research and development initiatives focusing on:

- Advanced Manufacturing Techniques: Innovations in crystal growth, precision machining, and nanostructuring to enhance optical performance, reduce manufacturing costs, and enable scalability.

- Expanded Applications: Exploration of new applications in fields such as biophotonics, environmental monitoring, and renewable energy technologies, leveraging ZnS windows’ unique optical properties and durability.

- Technological Integration: Integration of ZnS windows with advanced sensor technologies, wearable devices, and quantum-enabled systems for enhanced functionality and performance in diverse applications.

Conclusion

Zinc Sulfide (ZnS) windows represent a crucial component of modern IR optics, offering high transparency, mechanical robustness, and optical clarity across the infrared spectrum. As advancements in materials science, manufacturing techniques, and optical engineering continue to evolve, ZnS windows will play a pivotal role in advancing IR imaging, laser systems, scientific research, and defense applications. Leveraging the unique properties of ZnS, researchers, engineers, and innovators can drive innovation, develop new technologies, and address complex challenges in optics and photonics