Ultimate Guide to Types of Heat Sinks: Technology, and How It Works

Welcome to the world of heat sinks, where smart design keeps devices cool! Ever wondered how your laptop stays quiet or your gaming console runs smoothly? Heat sinks help by preventing overheating, ensuring your devices work efficiently. In this guide, we’ll explore different types of heat sinks, the technology behind them, and the science that keeps devices from overheating. Get ready to discover the secrets of effective heat management!

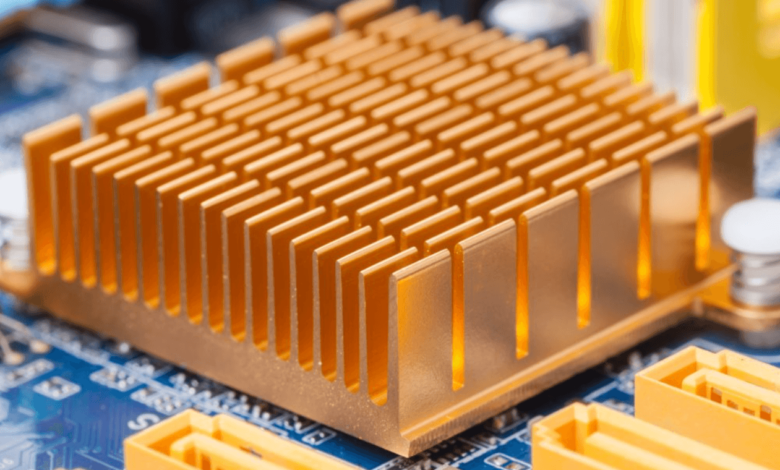

Understanding Heat Sinks

Heat sinks are crucial for keeping electronic devices cool and preventing overheating, which can cause failures or reduced efficiency.

Heat sinks absorb heat from processors and other important parts, then spread it across a larger surface to cool down more effectively. This helps keep the device running smoothly and extends its lifespan.

Heat sinks come in different shapes and sizes, designed for specific uses. Their effectiveness plays a big role in how well electronics function.

From computers and LEDs to power amplifiers, heat sinks quietly ensure technology stays cool and reliable.

Types of Heat Sinks

Heat sinks play a crucial role in keeping electronic devices cool by dissipating excess heat, ensuring efficiency and longevity. Different types are designed for specific applications and cooling needs.

1. Active Heat Sinks

Active heat sinks have fans or pumps that push air over their surface, helping to cool devices faster and prevent overheating in powerful electronics. Unlike passive heat sinks, which rely on natural airflow, active cooling uses fans to remove heat more quickly. Many modern designs have fans that adjust their speed based on temperature, making cooling more efficient while keeping noise levels low.

Active heat sinks are commonly used in high-performance computing, gaming PCs, and power-hungry devices where temperature control is critical. However, they may generate noise, though newer fan designs have significantly reduced this issue.

2. Passive Heat Sinks

Passive heat sinks operate without moving parts, using only natural convection and conduction to dissipate heat. Made from high-thermal-conductivity materials like aluminum or copper, they spread heat efficiently across their surface. Their finned designs help maximize airflow and cooling performance.

Since they don’t require power or fans, passive heat sinks are silent and highly reliable, making them ideal for applications like home theater systems, silent computing, and embedded electronics.

However, passive cooling may not be sufficient for high-power devices that generate a lot of heat. In such cases, a hybrid or active cooling solution may be needed for better thermal management.

3. Hybrid Heat Sinks

Hybrid heat sinks combine the advantages of both active and passive cooling systems to improve thermal performance. These designs typically feature a combination of fans, heat pipes, and fin structures to enhance heat dissipation.

In a hybrid setup, the fan increases airflow, while the fins or heat pipes maximize surface area, allowing for more efficient cooling. This dual approach ensures better temperature control without excessive energy consumption.

Hybrid heat sinks are especially useful in compact, high-performance devices where space is limited but effective cooling is crucial. They are commonly found in CPUs, LED lighting systems, and other advanced electronics. As technology continues to evolve, hybrid cooling solutions will become even more efficient and widely adopted.

Heat Sink Technologies

Advancements in heat sink technologies have significantly improved cooling efficiency in modern electronics, ensuring devices operate at optimal temperatures.

A. Finned Heat Sinks

Finned heat sinks improve heat dissipation by increasing surface area, enhancing airflow in passive (natural convection) and active (fan-assisted) cooling systems.

- Applications – Used in CPUs, LED lighting, and power electronics.

- Materials – Aluminum (lightweight, cost-effective) or copper (better conductivity, higher cost).

- Installation – Proper contact with components ensures efficient heat transfer and prevents overheating.

Their adaptability and efficiency make them essential for various cooling applications.

B. Vapor Chambers

Vapor chambers provide advanced thermal management by efficiently spreading heat across a surface. They are similar to heat pipes but offer better heat distribution, making them ideal for compact, high-performance devices.

These chambers function using phase-change technology.

A liquid inside the sealed chamber evaporates when heated, transforming into vapor. This vapor moves to cooler areas, where it condenses back into liquid form, continuously cycling to transfer heat away from hot components.

Benefits of vapor chambers include:

- Uniform heat distribution, preventing hot spots.

- Thin and lightweight design, making them suitable for compact electronics like CPUs and GPUs.

- Compatibility with other cooling technologies, such as finned heat sinks or fans, for enhanced efficiency.

Vapor chambers are particularly useful in high-performance applications, ensuring stable operation even under heavy workloads.

C. Loop Heat Pipes

Loop heat pipes (LHPs) are highly efficient thermal management solutions that transfer heat over long distances without mechanical pumps or fans. They use a sealed pipe filled with a working fluid that undergoes continuous evaporation and condensation.

The process works as follows:

- Heat causes the liquid at one end of the pipe to evaporate.

- The vapor travels to the cooler section, where it condenses back into liquid form.

- The liquid then returns to the hot area through capillary action, restarting the cycle.

Loop heat pipes offer several advantages, such as:

- High efficiency in heat transport, even in extreme conditions.

- Flexibility in orientation, allowing them to function in various positions.

- Reliability with no moving parts, reducing maintenance needs.

These properties make LHPs ideal for electronics cooling, aerospace applications, and spacecraft thermal control systems, where precision and durability are essential.

Choosing the Right Heat Sink

Selecting the right heat sink is essential for managing heat dissipation effectively and ensuring the longevity and performance of electronic components. Here’s how to make the right choice:

1. Assess Cooling Requirements

Begin by evaluating the heat output of your components. Higher power components generate more heat and require heat sinks with greater thermal dissipation capacity. The key factors to consider include:

- Power consumption

- Maximum safe operating temperature

- Required thermal resistance for efficient cooling

2. Consider Space Constraints

The available physical space determines the size and shape of the heat sink.

- Compact systems require smaller, efficient heat sinks.

- Larger setups can accommodate more advanced cooling solutions with larger surface areas.

3. Optimize Airflow

The effectiveness of a heat sink depends on the surrounding airflow:

- Active cooling: Uses fans or liquid cooling to improve heat dissipation, ideal for high-performance setups.

- Passive cooling: Relies on natural convection, making it suitable for low-power or silent operations.

4. Choose the Right Material

The material choice affects thermal conductivity and weight:

- Aluminum: Lightweight, cost-effective, and widely used for general applications.

- Copper: Superior thermal conductivity but heavier and more expensive, ideal for high-performance cooling.

5. Consider Noise Levels

For environments where silent operation is important, passive heat sinks (without fans) are preferable. If noise is not a concern, active cooling provides better thermal performance.

By balancing these factors, you can select a heat sink that optimizes thermal efficiency while fitting your system’s needs.

Read also: Integrating Cutting-Edge Technologies to Secure Enterprise Data

Maintenance and Care for Your Heat Sink

A heat sink helps keep electronic devices cool by removing excess heat, preventing overheating, and ensuring they work properly. Taking care of your heat sink can make it last longer and work better. Here are some simple maintenance tips:

- Regular Cleaning: Remove dust using compressed air or a soft brush; use isopropyl alcohol for deep cleaning.

- Check Thermal Paste: Inspect and reapply if dried or cracked to maintain heat transfer.

- Ensure Proper Airflow: Keep fans functional and arrange components to optimize airflow.

- Tighten Mounting Screws: Ensure firm contact between the heat sink and the component.

- Monitor Temperatures: Use software tools to track performance and adjust cooling if needed.

- Prevent Physical Damage: Handle with care to avoid bending and check for corrosion in humid environments.

By following these steps, you can extend your heat sink’s lifespan and maintain optimal cooling efficiency.