What is a VMC machine used for?

What is a VMC Machine Used For?

VMC machines, or Vertical Machining Centers, are pivotal in various manufacturing processes, offering precision and versatility for a wide range of applications. This comprehensive guide delves into the functions, benefits, and types of VMC machines, highlighting their essential role across different industries.

Introduction to VMC Machines

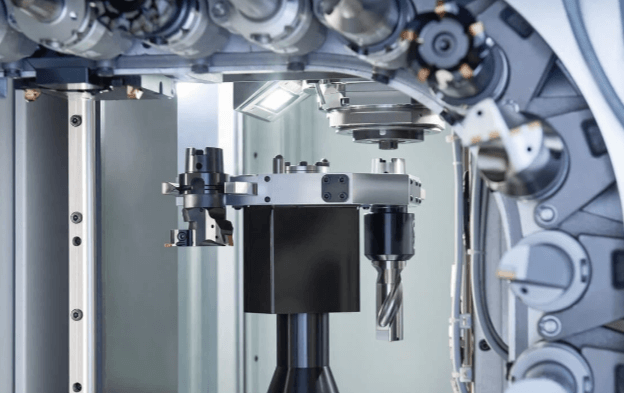

A Vertical Machining Center (VMC) is a type of CNC (Computer Numerical Control) machine that performs cutting, drilling, and milling operations with high precision. It features a vertically oriented spindle that facilitates intricate machining operations, making it ideal for creating complex shapes and high-precision parts.

Brief History of VMC Machines

The development of VMC machines began in the aftermath of World War II, evolving from manual milling machines to advanced CNC technology. This transition was driven by the need for more accurate and efficient manufacturing methods in industrial production.

Components of a VMC Machine

The spindle, the core of the VMC, holds and rotates the cutting tools at various speeds, crucial for achieving the machine’s high precision.

The control panel is the interface for the CNC system, where machine operators input commands and parameters that guide the machine’s movements and operations.

The tool changer automatically switches between different tools during operation, significantly reducing manual changeover time and enhancing production efficiency.

Primary Applications of VMC Machines

VMCs are extensively used in the automotive industry to manufacture complex parts such as engine components, gearbox cases, and suspension mounts, contributing to the industry’s high demands for precision and reliability.

Importance in Aerospace Engineering

In aerospace, VMCs are crucial for producing critical components like turbine blades and structural frames, where precision and material integrity are paramount.

Contributions to the Electronics Industry

The electronics industry benefits from the precise capabilities of VMCs in creating components like semiconductor housings and intricate molds for plastic connectors.

Manufacturing Medical Devices

VMCs play a vital role in the medical sector, particularly in fabricating orthopedic implants and surgical tools that require exact specifications for patient safety.

VMC Machines in Metal Fabrication

Metal fabrication shops utilize VMC machines for detailed cutting, drilling, and finishing operations, enabling them to work with a variety of metals and composite materials.

Types of VMC Machines

These compact units are ideal for smaller projects or educational purposes, providing the capability to learn and practice machining in a more accessible format.

For large-scale industrial applications, these machines handle substantial projects that require handling large parts and heavy materials.

Specialty VMC Machines for Unique Applications

Designed for projects requiring exceptionally high speeds, these machines reduce cycle times and increase productivity.

Offering additional axes of movement, multi-axis VMCs enable the machining of complex geometries without the need for multiple setups, thus enhancing precision and reducing operation time.

Benefits of Using VMC Machines

VMCs are renowned for their precision, crucial in industries where even minute discrepancies can lead to significant consequences.

The automation capabilities of VMC machines streamline production processes, allowing for faster, more consistent output with minimal human intervention.

Able to perform various machining tasks, VMCs are valuable for their versatility, handling different materials and parts with ease.

Though VMCs require a significant initial investment, their long-term efficiency and durability offer substantial cost savings through reduced labor costs and minimized waste.

Setting Up a VMC Machine

Proper installation of a VMC involves ensuring sufficient space, stable power supply, and controlled environmental conditions to maintain operational accuracy.

Adhering to stringent safety standards is crucial in preventing accidents and maintaining safe operations, particularly when operating high-speed machinery.

Operators of VMC machines require specialized training in CNC programming and operations, emphasizing both machine capabilities and safety practices.

Maintenance and Troubleshooting VMC Machines

Regular maintenance is essential for sustaining the high performance and longevity of VMC machines, involving periodic inspections and servicing.

Understanding common issues such as alignment errors or tool wear can help operators quickly troubleshoot and maintain continuous operation.

Properly maintained VMC machines can operate effectively for many years, making them a long-term investment in manufacturing capabilities.

Real-world Examples of VMC Machine Applications

Numerous case studies demonstrate how VMCs have significantly improved efficiency and productivity in sectors like automotive and aerospace manufacturing.

Success stories across various fields underscore the transformative impact of VMC technology in enhancing product quality and manufacturing precision.

The consistent performance of VMC machines ensures high-quality outputs, crucial for maintaining standards in industries requiring high precision.

FAQs About VMC Machines

- What is the cost of a typical VMC machine?

- Costs can range from $50,000 for a basic model to over $500,000 for advanced, multi-axis machines, depending on features and capabilities.

- How to choose the right VMC machine for your business?

- Evaluate the specific machining needs, including the types of materials, part sizes, and precision requirements, and consider factors like machine size, power, and technological features.

- What training is required to operate a VMC machine?

- Comprehensive training in CNC programming, machine operation, safety protocols, and maintenance is crucial for effective and safe operation.

Conclusion

VMC machines are integral to modern manufacturing, offering unmatched precision, versatility, and efficiency. As technological advancements continue to evolve, the capabilities and applications of VMC machines are expected to expand, further solidifying their role in industry.